Here’s a good bit of it.

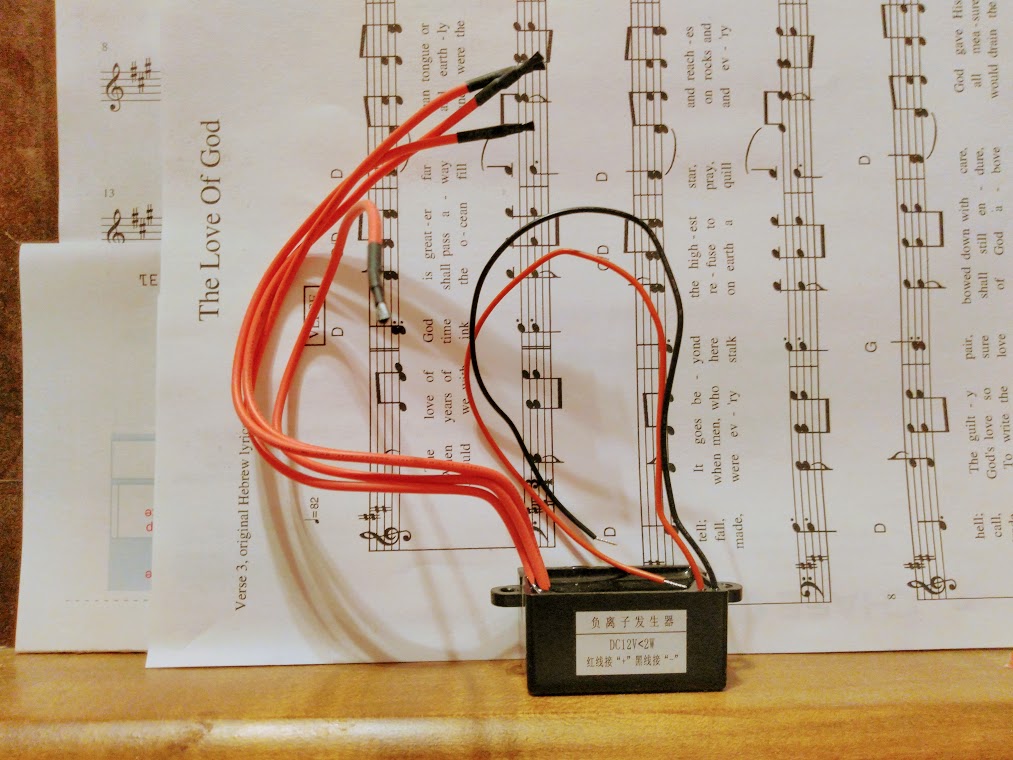

- For a number of decades, there have been “negative air ionizers” available retail, for the home. These give negative static electrical charge to air particles, as found after a thunderstorm.

Starting in the twenty-oughts or so, there was a ramp-up, and negative air ionizers were added to many air conditioners and other HVAC products, because in addition to apparent health benefits, dust and other impurities tend to drop out of ionized air, and filters become more effective. Anyway, in 2017 I was faunching to do something interesting with my 1998 Chevrolet Tahoe, and my dad had helped me understand that I really really didn’t want to try heating the fuel (worked well with a carburetor I had years before…), and it occurred to me that I could try this. And then I did a bit of searching, and found that there is a very nice industry-standard form factor now, little sealed electrical boxes just needing power, with their own little carbon-fiber brushes.

Starting in the twenty-oughts or so, there was a ramp-up, and negative air ionizers were added to many air conditioners and other HVAC products, because in addition to apparent health benefits, dust and other impurities tend to drop out of ionized air, and filters become more effective. Anyway, in 2017 I was faunching to do something interesting with my 1998 Chevrolet Tahoe, and my dad had helped me understand that I really really didn’t want to try heating the fuel (worked well with a carburetor I had years before…), and it occurred to me that I could try this. And then I did a bit of searching, and found that there is a very nice industry-standard form factor now, little sealed electrical boxes just needing power, with their own little carbon-fiber brushes.

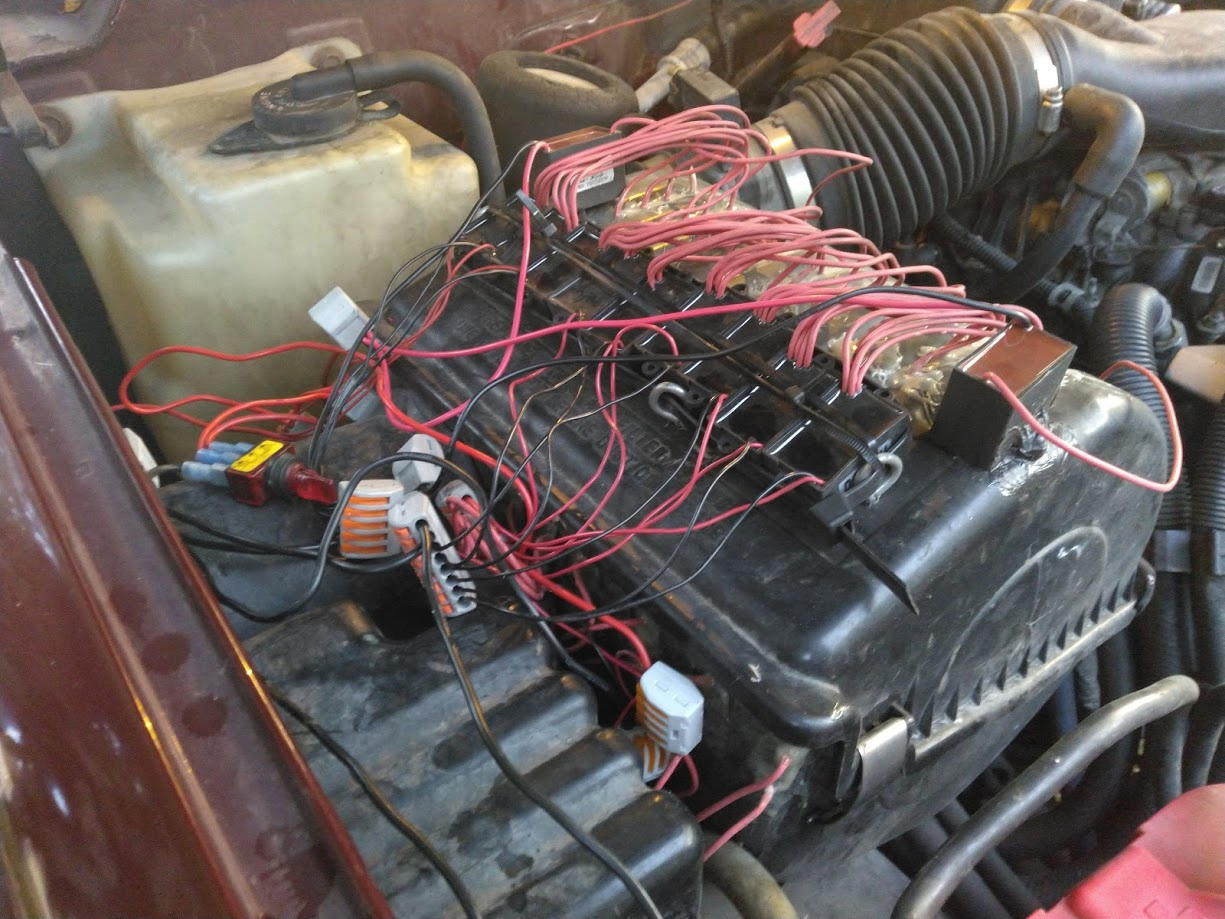

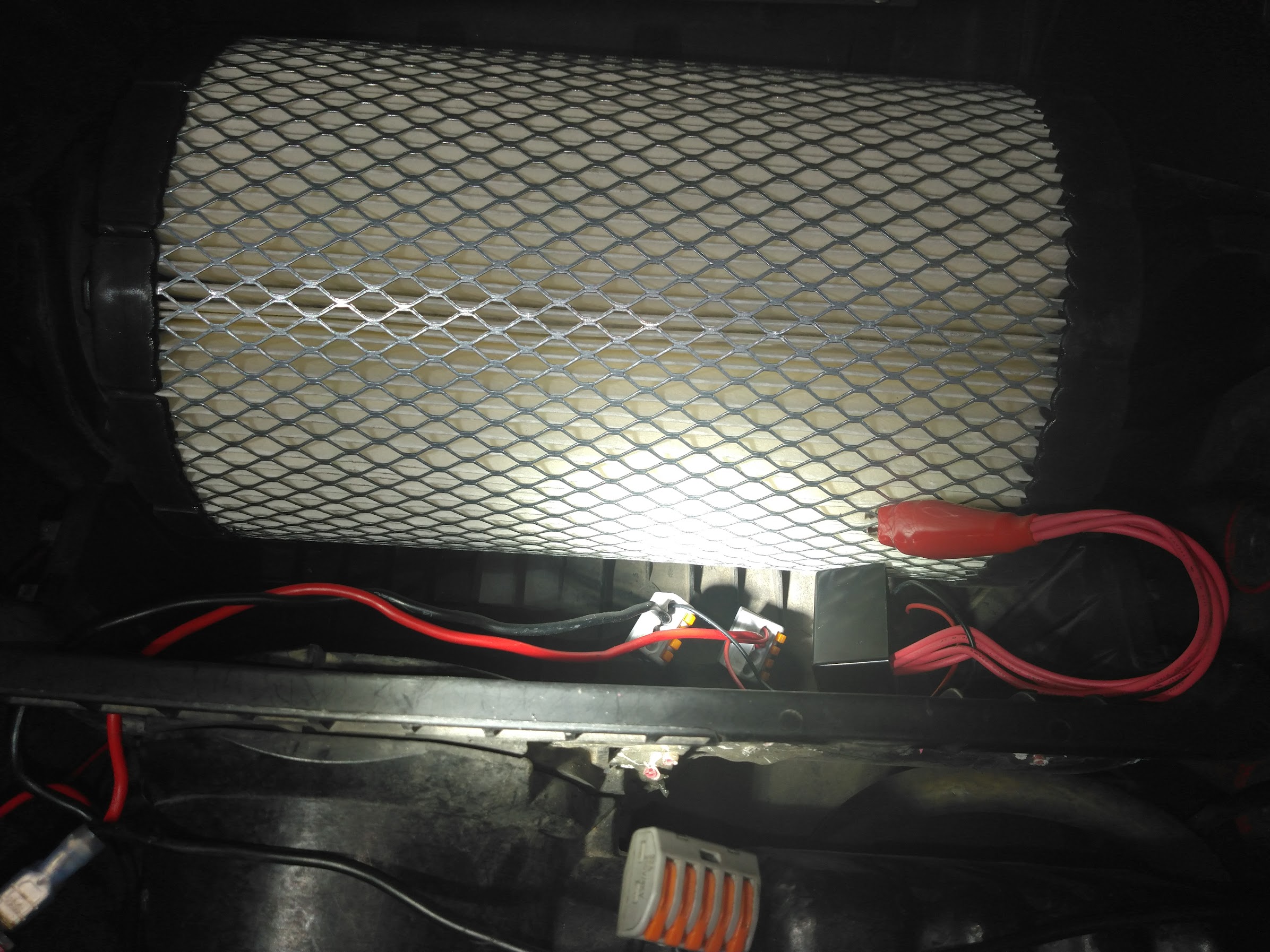

From 2018 to mid-2021, I built from 1 to 14 negative ionizer units into the filter compartment of my Tahoe. The first install was done in the heart of a very cold winter (some winters are very cold here), and clearly helped the V8 handle it. The collection worked nicely, and increasingly so, but the behavior over time didn’t match the changes in the setup. There were unexplained engine hesitations that came and went, which appeared to go away at fourteen, but results still didn’t match. At this time, the the electronics were mounted on the outside of the air filter container, and carbon fiber brushes were glued into holes drilled. The culmination is shown in the first picture above. The second picture shows the inside of the air filter compartment, with the carbon-fiber ends sticking through. At the back is an experiment, a custom-fabricated carbon fiber brush, to which I had attached the last two electronics packages, mounted on the outside in back.

From 2018 to mid-2021, I built from 1 to 14 negative ionizer units into the filter compartment of my Tahoe. The first install was done in the heart of a very cold winter (some winters are very cold here), and clearly helped the V8 handle it. The collection worked nicely, and increasingly so, but the behavior over time didn’t match the changes in the setup. There were unexplained engine hesitations that came and went, which appeared to go away at fourteen, but results still didn’t match. At this time, the the electronics were mounted on the outside of the air filter container, and carbon fiber brushes were glued into holes drilled. The culmination is shown in the first picture above. The second picture shows the inside of the air filter compartment, with the carbon-fiber ends sticking through. At the back is an experiment, a custom-fabricated carbon fiber brush, to which I had attached the last two electronics packages, mounted on the outside in back.

- With just six of the ionizer units in place in the Tahoe, Sweet Lori and I made a careful 40-mile circle run repeated twice, outside temperature the same, after the engine was well into its steady hot state, first with the rig turned on, then with it off. We saw a 2.8% improvement in gas mileage.

- On the Dodge truck, just two charger units was the rule, and they helped, and even permitted good behavior using E-85 gasoline. The above was the progression of things for almost two years.

During this period, something mysterious happened to spark plug #4, on my Tahoe, which was replaced. My mechanic friend Matt said that #4 had the least compression, on this particular engine. Eventually I set up a temperature switch, so that the ion-injection rig runs only when the temperature of the inside of the air filter compartment, is higher than 35 F (1.67 C). Much more on this later.

During this period, something mysterious happened to spark plug #4, on my Tahoe, which was replaced. My mechanic friend Matt said that #4 had the least compression, on this particular engine. Eventually I set up a temperature switch, so that the ion-injection rig runs only when the temperature of the inside of the air filter compartment, is higher than 35 F (1.67 C). Much more on this later.

- But the desire was to make this practical in general, and to push the envelope, to see how much improvement is available, with more predictability. And fourteen little boxes, with four little wires coming off of most of them, did seem a bit excessive ☺ So in mid-2021, after a lot of pondering, a thought which had been quietly talking to me for some time, was implemented.

On the Tahoe, the standard air filter is held together by a metal mesh, so I added a single electronics package, with all four leads combined, clipped to the mesh. The response to this was amazing. Bertha’s (the Tahoe’s) engine literally howled the first time it was started with this. So I unplugged all the fourteen others that were still engaged, and ran with the one clip. The result was still quite astonishing, it appeared that the one clip was doing more than all fourteen “ambient” combined.

On the Tahoe, the standard air filter is held together by a metal mesh, so I added a single electronics package, with all four leads combined, clipped to the mesh. The response to this was amazing. Bertha’s (the Tahoe’s) engine literally howled the first time it was started with this. So I unplugged all the fourteen others that were still engaged, and ran with the one clip. The result was still quite astonishing, it appeared that the one clip was doing more than all fourteen “ambient” combined.

- Multiple setups were tried over the next months. Sometimes it ran steady and well. Plug #4 fouled a number of times, as did #3 and #6. Matt said that all of these cylinders were relatively low in compression compared to the rest. I was seeing more consistency with just the clip and variations within it, so I removed all of the other electronics packages (and sealed up all of the holes with plastic-bonding epoxy), just leaving the single clip attached to the mesh on the air filter. For vehicles with no mesh on their filter, I plan to add stainless-steel mesh to their filters, the geometry seems quite simple.

- And then, when outside air temperature dipped below 32 degrees F, immediately it occurred that the engine ran a bit rough. I pulled over and switched to a clip with just two leads combined, and then just one lead, and noticed that it got worse, not better, and also, the other electronics packages made more of their typical quiet noise than the original. I disconnected it all, and it was clear that a spark plug had gone bad. So I immediately dosed the gas with lots of Techron, which minimized the situation until I could get Matt to replace it again (it was #4, the usual), but there appeared quite the learning:

- Not all of the electronics packages I had been using, were consistent in output. A method to measure before mounting, is necessary. We have one now, thanks to a contributor; it is helping quite a lot to set new planning and analysis in good order.

- There is a clear drop in how much ion delivery is appropriate, somewhere near 32 degrees F. This has to be remembered carefully.

- Once the temperature switch was in place (much later), and set to 35F (1.67C), an excellent stability appeared. When outside air is around 20F (-6.667C), it can take about 15 minutes for the inside of the filter compartment to reach 35F (1.67C), but it’s very well worth it, this is clearly the way forward.

- When I bought Bertha (the Tahoe), I was told that it has an aftermarket flow-through exhaust system, which requires 91 octane or higher for good behavior, including preventing plugs from fouling, which was corroborated sometimes (and not always) elsewhere. However, through trial and error, I learned that with this rig set up, 87 octane works much better. So 87 it is!!!

- I bought a variety of single-output air charger units, different makes and models, but all of them except one of the variety with the little carbon-fiber brushes on their business-ends. I tested them all with the meter, and very nearly every one put out about 10 million particles per cubic cm measured at (industry-standard) 10cm distance, by each output wire. The four-wire units put out approximately 10 per wire; the single-wire unit put out 10.

- The only one which didn’t fit the above, was one which used little metal pins. This was a total dud, even though one could smell ozone (!) (not desireable!) and see the corona discharge on its metal pins. The meter showed it was putting out almost no ionized air particles at all.

- And so, in early January 2022, I set up a nicely functional and mostly stable setup on Bertha’s engine.

I bought some small (less than one cubic inch) DC voltage regulator/converters, which take the 11.5-to-15 volts from the electrical system and put out a very stable 5.0 volts. I tested one of my 12VDC single-output air charger units with 5.0 volts, and it put out about 4 M/cm3 @ 10cm. I wired the output of that unit to a clip, clipped onto the air filter.

I bought some small (less than one cubic inch) DC voltage regulator/converters, which take the 11.5-to-15 volts from the electrical system and put out a very stable 5.0 volts. I tested one of my 12VDC single-output air charger units with 5.0 volts, and it put out about 4 M/cm3 @ 10cm. I wired the output of that unit to a clip, clipped onto the air filter.

- This was much better, but still not good enough, plug-foulings still occurred occasionally.

And all of those occurred during cold, so I set up the temperature switch. This appears to be keeping things very nice indeed. At first my mark was 20F / -6.67C, and that seemed to do very nicely until one day of all of cold, wet, and icy. So I switched to 35F / 1.67C. The pictured temperature switch component worked very well, but about half of the LEDs of the display had died after a full year of engine-compartment conditions; I used a spare for a while, and then began to use another built by a friend, Arduino-based. More on that in the future ☺

And all of those occurred during cold, so I set up the temperature switch. This appears to be keeping things very nice indeed. At first my mark was 20F / -6.67C, and that seemed to do very nicely until one day of all of cold, wet, and icy. So I switched to 35F / 1.67C. The pictured temperature switch component worked very well, but about half of the LEDs of the display had died after a full year of engine-compartment conditions; I used a spare for a while, and then began to use another built by a friend, Arduino-based. More on that in the future ☺

- And as of March of 2024, the next big step is in place! This is Stage II, where a lot more negative ions are thrown in when engine RPM rises above approximately 1100.

Two commercially-available RPM switches failed to work as advertised on this ’98 Tahoe, but a third one, the MSD 8950 with the adjustable RPM module, is working well. The one single-output clip runs at engine startup (temperature permitting!), but at 1100 RPM, two more quad-output clips (eight clips in all additional) run, and also, two more quad-output “ambient” with the little carbon-fiber brushes in air. The result of all of this has been startlingly good behavior, steady as a rock, nice under foot, tested in atmospheric from 21F (-6.1C) to 71F (21.67C) so far. I also have some LEDs mounted in view from the driver’s seat; the left LED lights when the system is on (a.k.a. when the temperature switch turns it on), the right one lights by the RPM switch.

Two commercially-available RPM switches failed to work as advertised on this ’98 Tahoe, but a third one, the MSD 8950 with the adjustable RPM module, is working well. The one single-output clip runs at engine startup (temperature permitting!), but at 1100 RPM, two more quad-output clips (eight clips in all additional) run, and also, two more quad-output “ambient” with the little carbon-fiber brushes in air. The result of all of this has been startlingly good behavior, steady as a rock, nice under foot, tested in atmospheric from 21F (-6.1C) to 71F (21.67C) so far. I also have some LEDs mounted in view from the driver’s seat; the left LED lights when the system is on (a.k.a. when the temperature switch turns it on), the right one lights by the RPM switch.

The whole system now runs from one Drok buck-boost DC power supply, taking it to a very steady 12VDC; thus far everything has been just fine at 35F/1.67C as 12VDC. Behavior is very nice!

The whole system now runs from one Drok buck-boost DC power supply, taking it to a very steady 12VDC; thus far everything has been just fine at 35F/1.67C as 12VDC. Behavior is very nice!

- So the next step, is another 40-mile-or-so fuel economy test, and after that, dynamometer testing, I finally located two places in Kansas City which will do three dyno-tests for $75! And I’m starting to look again at my sweet Lori’s car… ☺

Have a great day!

J.E.B.